Consumers around the world, especially those in the health and wellness industry, have been increasingly concerned with having adequate levels of protein in their diets. In response to this, protein has become a crucial macronutrient in food product development and labeling. While many manufacturers display protein claims on their products, not all protein is equal or essential for the consumer.

The Protein Digestibility-Corrected Amino Acid Score (PDCAAS) is the official FDA method for evaluating protein quality in human nutrition and how well your body digests and absorbs protein from different sources. This scoring system has changed how food manufacturers formulate products and make protein content claims.

This article will explore the significance of PDCAAS in food product development, how it impacts product claims and marketing strategies, and the growing regulatory emphasis on protein quality verification. Whether you’re a food manufacturer or restaurant owner, understanding PDCAAS is essential for creating products to meet regulatory requirements and consumer expectations for high-quality protein.

To see how our software simplifies the complexities of PDCAAS and other nutrient claims, you can create a free label or view our pricing plans.

See How FoodLabelMaker Can Help You

Understanding Essential Amino Acids Profiles

Amino acids are components of proteins that add to the foundation of our body’s tissues, organs, and enzymes. There are over 20 amino acids that your body needs as human protein requirements to function optimally. Nine of these amino acids, known as Essential Amino Acids (EAAs), are fundamental sources of protein that cannot be made by the human body and must be obtained through food and diet. The nine essential amino acids are histidine, isoleucine, leucine, lysine, methionine, phenylalanine, threonine, tryptophan, and valine. These play crucial roles in protein synthesis, metabolism, and overall health.

In nutrition labeling, amino acid profiles break down which amino acids are in your ingredients. This profile helps determine the quality of protein in food products and is used to calculate the PDCAAS score.

The FDA has established reference patterns based on the amino acid requirements of preschool-age children. The Essential Amino Acid Requirements (mg/g protein) in amounts are:

- Isoleucine: 28

- Leucine: 66

- Lysine: 58

- Methionine + Cysteine: 25

- Phenylalanine + Tyrosine: 63

- Threonine: 34

- Tryptophan: 11

- Valine: 35

Profiling and analysing these amino acids are typically conducted using several methods, some of which include:

- High-Performance Liquid Chromatography (HPLC): The most commonly used method that separates amino acids based on column interaction.

- Gas Chromatography (GC): Used after derivatization for volatile amino acids and as an alternative method to HPLC.

- Ion-Exchange Chromatography: The most traditional method of separating amino acids by charge.

Measuring amino acid content using these methods is essential for:

- Evaluating protein quality

- Verifying nutritional claims

- Meeting regulatory requirements

- Influencing product development decisions

Accurate profiling of amino acids and analysing them is also essential for products that contain substantial amounts of protein or products that require protein claims. These include examples like infant formulas, meat and dairy products and plant-based foods.

PDCAAS Calculation and Implementation

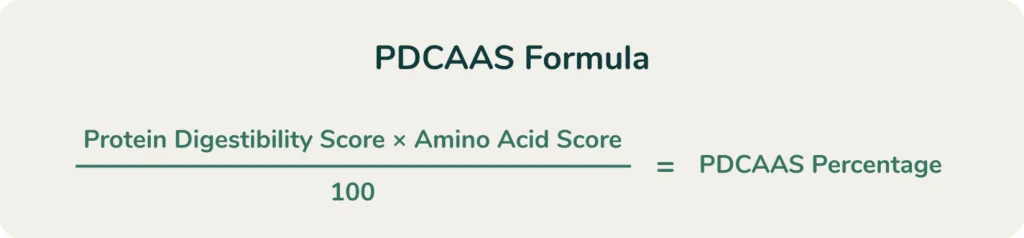

Protein Digestibility-Corrected Amino Acid Score (PDCAAS) evaluates protein quality by comparing its amino acid composition to human requirements and adjusting for digestibility. PDCAAS values range between 0 and 1, with 0 being the poorest quality protein that cannot be absorbed as easily and 1 being the best quality that can be absorbed easily.

Acquiring the recipe’s protein digestibility score is often done through lab analysis. The Amino Acid Score is determined either through a lab analysis that performs amino acid profiling using HPLC (High-Performance Liquid Chromatography), or through the Food Label Maker Software using our in-depth Amino Acids Pattern Report. The final PDCAAS value is calculated by simply multiplying the Amino Acid Score by the protein digestibility score.

Typical Reference PDCAAS Values for high protein food products are:

- Casein: 1.0

- Whey protein: 1.0

- Soy protein isolate: 1.0

- Beef: 0.92

- Pea protein concentrate: 0.89

- Black beans: 0.75

- Rice: 0.50

- Wheat gluten: 0.24

The FDA requires PDCAAS calculations to determine what protein content claims manufacturers can make on their food labels. If a product contains protein amounts that is manageable for the consumer to digest, the product can display a clear protein claim compared to other products with less protein or protein that is more difficult to digest.

For example, a product containing 10g of wheat protein (PDCAAS 0.24) would only provide 2.4g of usable protein, meaning it cannot make the same protein content claims as a product with 10g of whey protein (PDCAAS 1.0), which provides all 10g of usable protein – this ensures consumers get accurate information about the true nutritional value of protein sources in their food.

Making Compliant Protein Claims

When it comes to making protein claims on food labels, accuracy and compliance are essential. The FDA has established clear guidelines to help manufacturers make truthful claims while ensuring consumers receive reliable information about the protein content in their food.

Understanding FDA Protein Claims

To make a protein claim on your product, you need to meet specific thresholds:

- If you are making a “good source of protein” claim, your product must have at least 5 grams of protein per serving and it must be 10% of the Daily Value (%DV).

- If you are making an “excellent source of protein” claim, your product must provide at least 10 grams of protein per serving and it must be 20% of the Daily Value.

However, these amounts must be adjusted based on the protein’s PDCAAS score. Here is a simple example:

If your product contains 10 grams of wheat protein (PDCAAS = 0.24):

- Actual usable protein = 10g × 0.24 = 2.4g

- This product cannot make either protein claim, despite containing 10g of total protein

In contrast, if your product contains 10 grams of whey protein (PDCAAS = 1.0):

- Actual usable protein = 10g × 1.0 = 10g

- This product can make an “excellent source” claim

Documentation and Compliance

To support protein claims, manufacturers need to:

- Document PDCAAS calculations for their chosen protein source(s)

- Keep records of protein content testing

- Ensure the Nutrition Facts panel reflects the adjusted protein content

- Include the percent Daily Value (%DV) for protein when making claims

Benefits for Food Manufacturers

Understanding and implementing proper PDCAAS scoring and protein analysis offers significant advantages across multiple aspects of food manufacturing operations. Here’s how businesses can leverage these tools to enhance their products and market position:

Product Development Benefits

Efficient protein assessments have transformed product development, as research and development teams can quickly evaluate different protein sources and their impact on overall formulation quality. Modern analytical tools allow for this rapid feedback, enabling manufacturers to save on development time and cost while maintaining desired protein claims.

For example, a food manufacturer could calculate whether a more cost-effective blend of pea and rice protein could achieve similar PDCAAS scores to a whey protein formulation.

Marketing Advantages

High-quality protein claims, when properly substantiated, provide powerful marketing advantages. Manufacturers can confidently sell premium products if they have accurate and proven high protein quality scores. This is particularly useful in categories like sports nutrition, as customers will be more inclined to purchase products with high levels of protein.

Compliance Benefits

Proper implementation of PDCAAS and amino acid scoring significantly reduces compliance risks. Accurate calculations are essential to prevent labeling errors that could lead to fines or product recalls. Manufacturers can also streamline their processes by using software designed to accurately and effectively calculate these amounts while being compliant with current regulations.

This approach protects manufacturers against compliance issues and reduces the time and resources needed to outsource such a service. This also allows teams to refocus their efforts on innovation and other operations instead of spending time on testing or paperwork.

Software Solutions for PDCAAS and Amino Acid Score

Modern food manufacturers can now leverage sophisticated software solutions to streamline the complex process of protein quality assessment. These tools transform what was once a time-consuming manual calculation into an efficient, automated process. Food Label Maker offers an integrated software solution that simplifies these processes while ensuring accuracy and compliance, including a critical Amino Acid Pattern Report feature.

The software offers:

- Instant PDCAAS calculations based on ingredient inputs

- Comprehensive amino acid profiling through our Amino Acid Pattern Report

- Automatic nutrition claim suggestions

- Real-time adjustment of protein Daily Values

- Customization features that allow you to edit or add nutrient values

- Optimization possibilities for recipes based on improved nutritional profiles

Food Label Maker’s Amino Acid Pattern Report, which can be easily accessed on your dashboard, is a critical first step in the PDCAAS calculation process, providing the key data needed to determine a protein’s quality.

Their software undergoes automatic updates to ensure that it reflects the latest FDA guidelines or follows the requirements of the country you are selling your product. It also offers recipe management and recipe costing features that save time and costs in the long run. View their comprehensive Regulatory Hub or video tutorials for more on accurate and compliant food labeling.

Future Trends and Considerations For PDCAAS Scoring and Protein Analysis

As the market for protein-rich products expands, PDCAAS scoring and protein quality assessment continue to evolve. Manufacturers must validate their protein claims with accurate, scientifically backed data and develop products that accurately reflect these amounts. The industry may see a transition to even more precise measurement methods, such as DIAAS (Digestible Indispensable Amino Acid Score), which could provide enhanced accuracy in protein quality assessment.

For food manufacturers, staying competitive in this evolving landscape requires robust systems for protein quality testing. Food Label Maker’s software addresses these challenges by automating PDCAAS calculations, streamlining regulatory compliance, and providing relevant data required for protein claims. As consumers become more educated about protein, the ability to quickly and accurately assess protein quality while maintaining regulatory compliance will become increasingly crucial for success in the industry.

Create a free label to see our solution in action or view our pricing plans to find the best option for your business.