Accurate Recipe Yield Adjustment Software for Food Labels

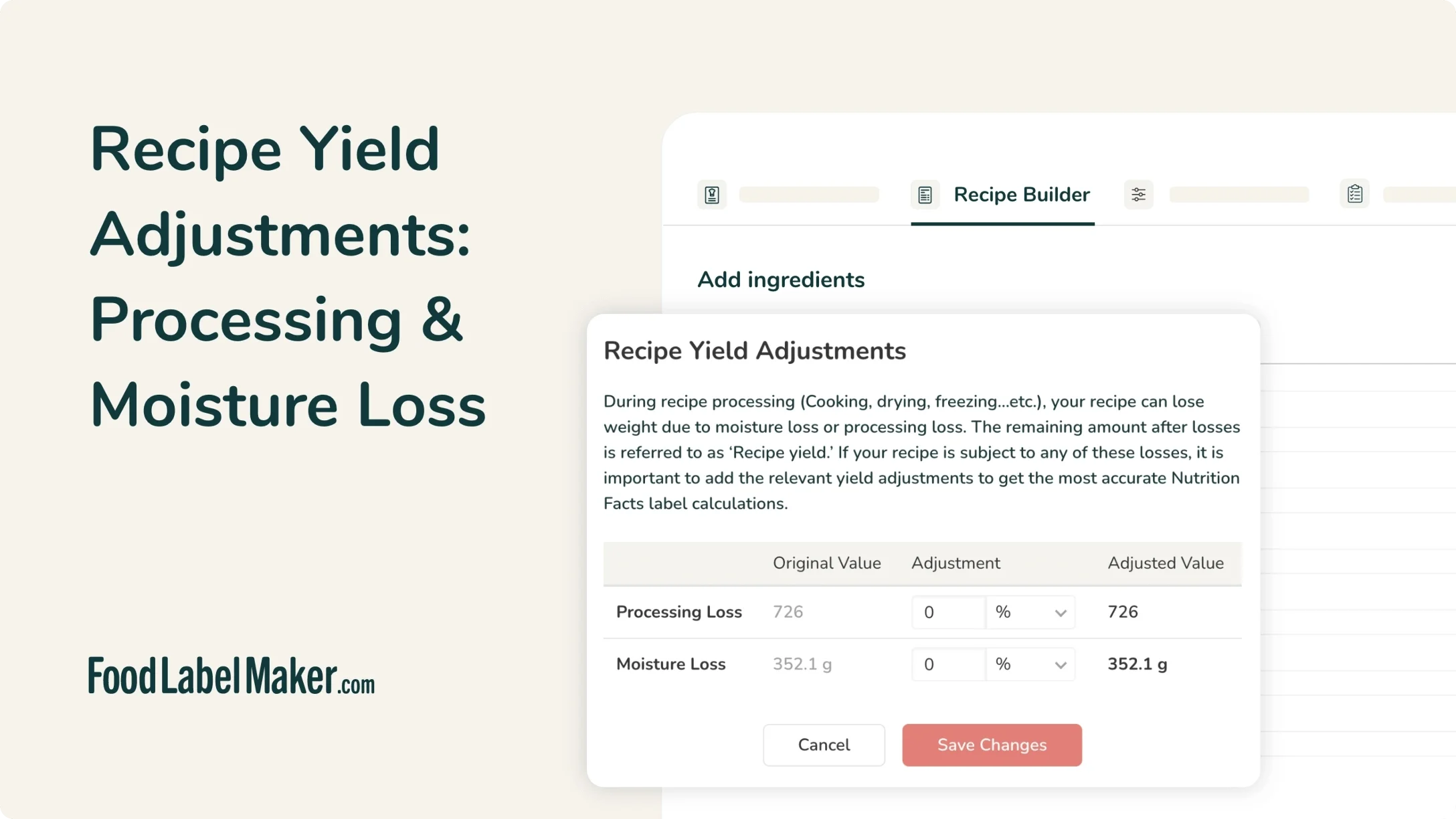

Recipe yield is the remaining food product amount after accounting for weight loss or moisture evaporation during cooking.

Our recipe yield adjustment software accurately calculates these changes, helping you manage all your recipes, ensure compliance, and avoid costly labeling errors on all your food labels.

Key Benefits of Recipe

Yield Adjustment Software

Our recipe yield adjustment software empowers businesses to have more autonomy over food costs, recipe ingredients, and overall quality control.

It helps you accurately calculate changes in yield during cooking or processing – whether for a recipe, prepared meal, or food product – so you can scale production consistently and confidently.

Accurate Nutrient Values

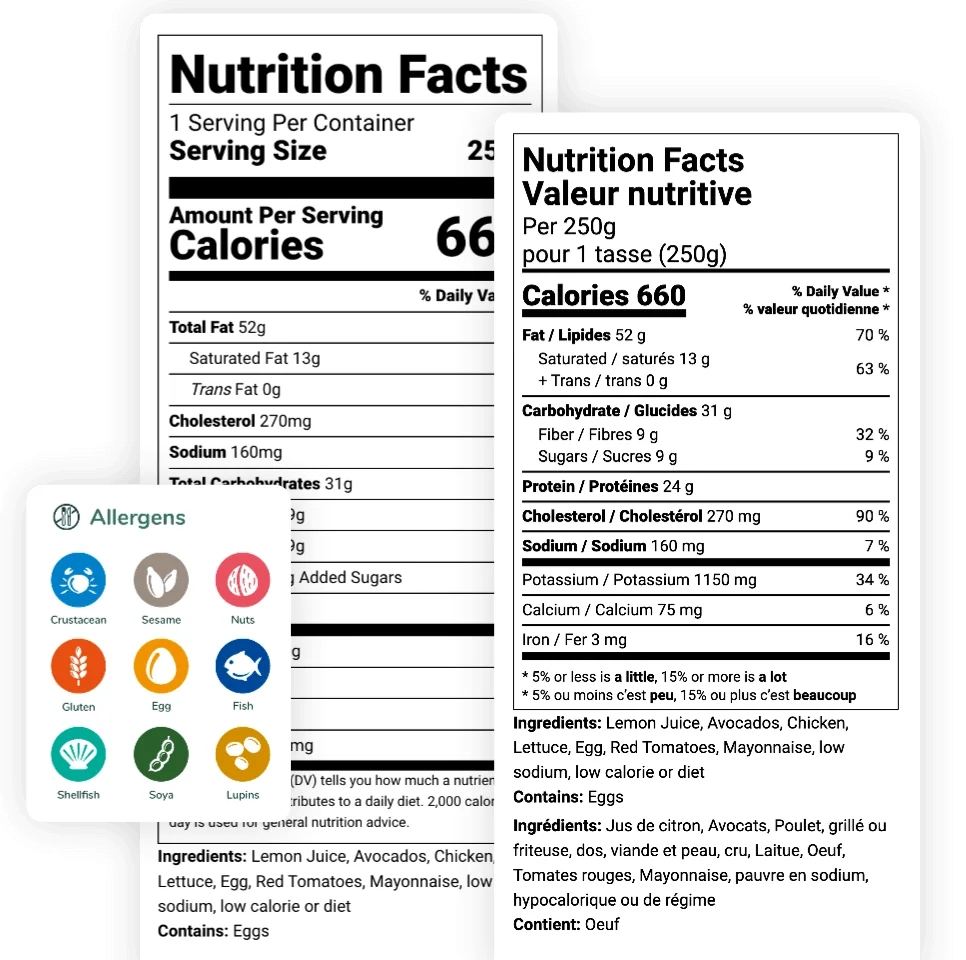

Adjusting for yield means your label reflects the actual nutrition in the final, ready-to-eat product, not just in the raw ingredient totals.

This is crucial for cooked foods, sauces, baked goods, and dried snacks, ensuring precise recipe costing and nutrient declarations.

Global Market Compliance

The FDA and CFIA, along with all other major markets, expect nutrient values to reflect the edible form of your product or meal as it’s sold or consumed.

Yield adjustments keep your declared values compliant and consistent, which are both crucial steps for operations and audits

Alignment with Real- World Kitchen Practices

Food often changes in weight or volume during production due to factors like water evaporation, fat loss, or portion shrinkage.

Yield control helps R&D teams, chefs, and manufacturers track and manage losses, reduce food waste, and ensure consistent results from production to plate.

Hear What Our Clients Have to Say

From food manufacturers and catering companies to restaurants and cafés, here’s what our clients have to say about the difference Food Label Maker’s intuitive software has made in their day-to-day operations.

Whether a business requires recipe scaling, precise recipe costing, or optimizing food costs across their entire menus, Food Label Maker’s recipe yield adjustment software and user-friendly tool offer control and compliance for global businesses.

About Us

Food Label Maker is a specialized online tool designed for food manufacturers, co-packers, and brand owners who need fast, accurate nutrition labels. From allergen detection and recipe costing to multilingual support, our platform helps streamline label creation and ensure compliance with FDA, EU, and other global regulations.

With easy-to-use features and automated compliance checks, Food Label Maker simplifies the process of generating nutrition facts panels, giving businesses the confidence to scale across markets without worrying about labelling errors.

Create Compliant Nutrition

Facts Labels Today

Frequently Asked Questions

About Recipe Yield Adjustment Software

The yield of a recipe refers to the final amount of food a recipe produces. It is typically measured by weight (e.g., pounds, kilograms), volume (e.g., cups, liters), or by the number of servings.

When a recipe involves cooking methods like frying, freezing, drying, or other processing, the yield can differ from the initial raw ingredient weight due to factors like moisture loss (evaporation) or fat rendering.

Understanding and adjusting for this final yield is crucial for accurate recipe costing, portion control, and more precise food labeling.

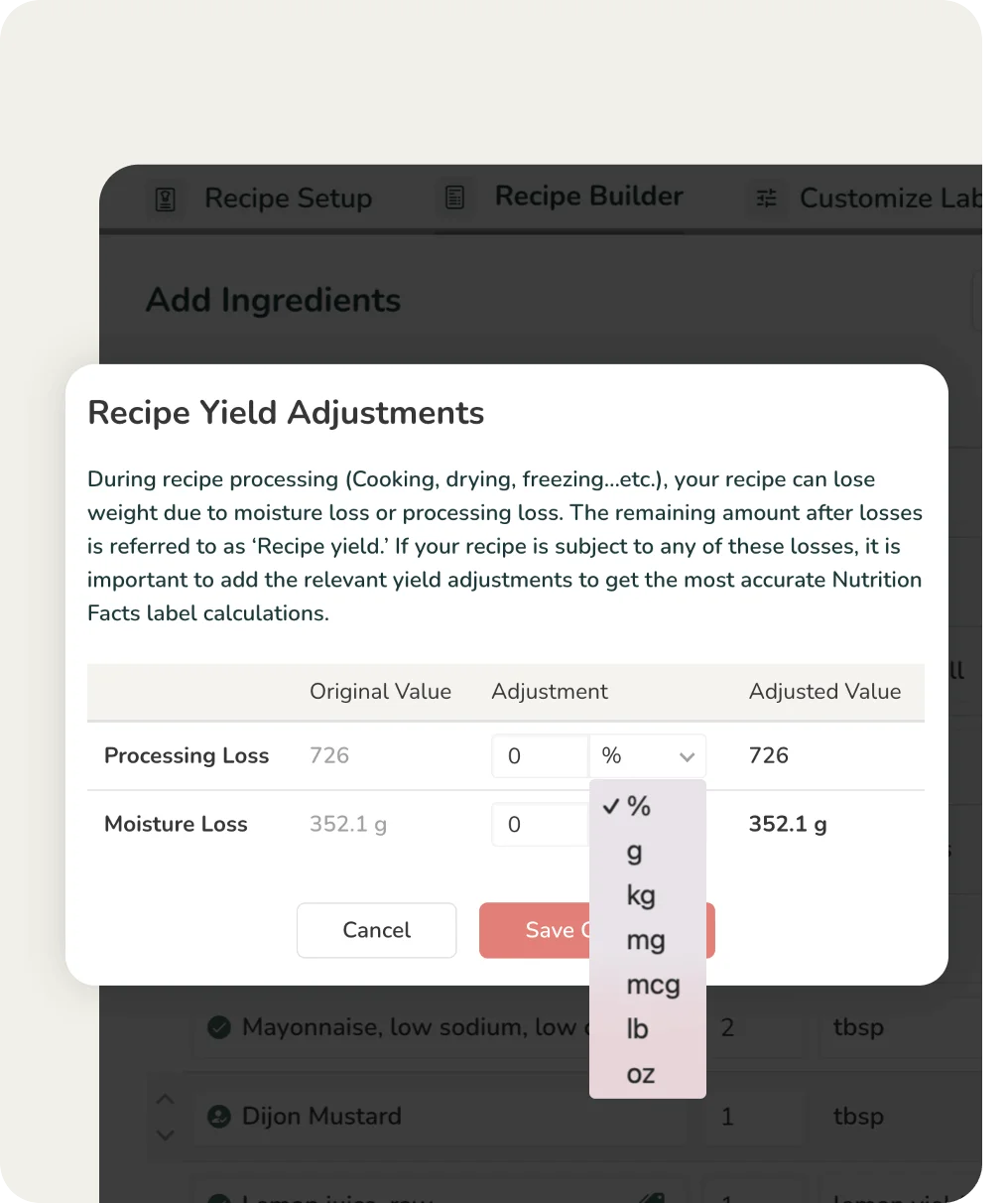

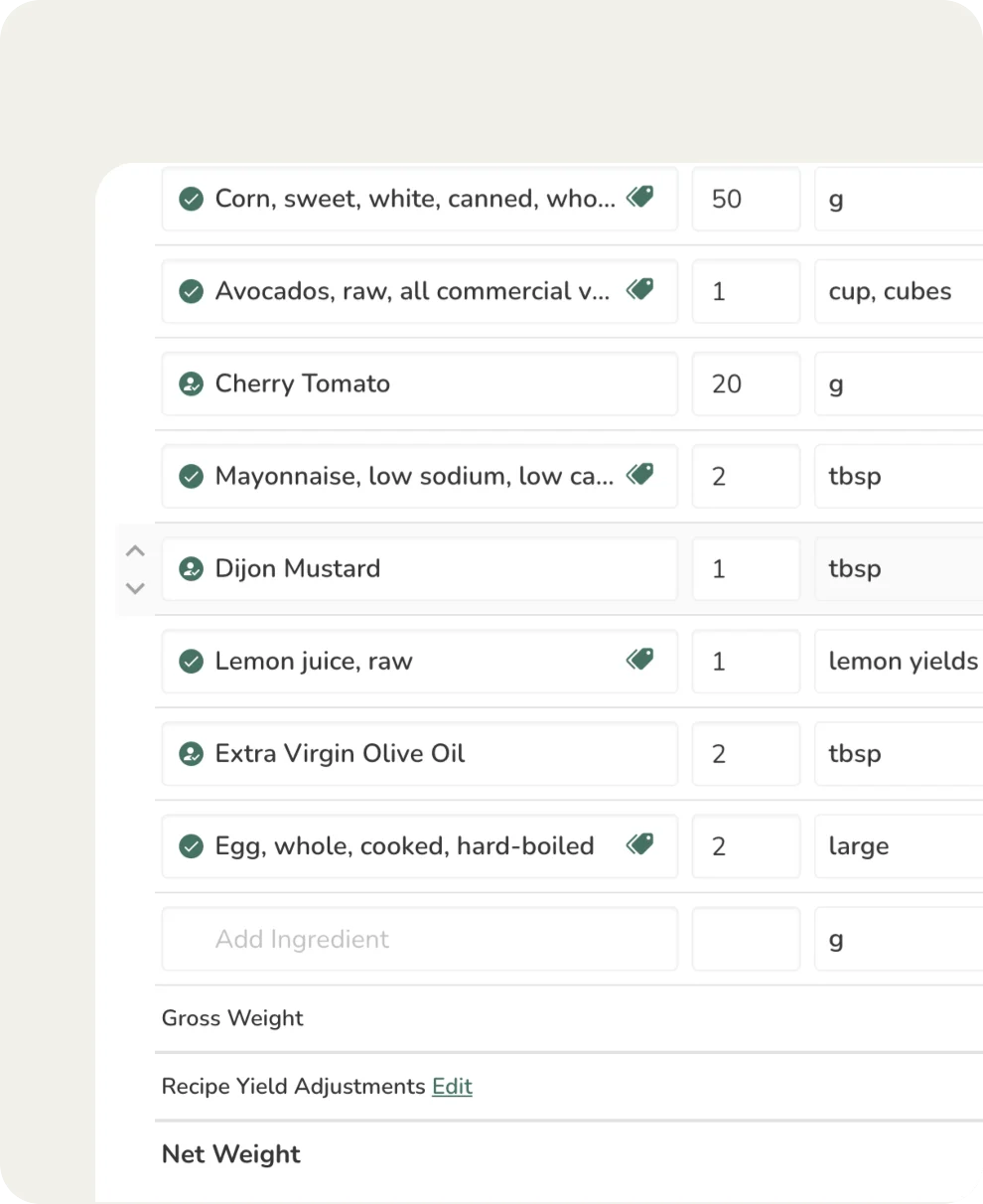

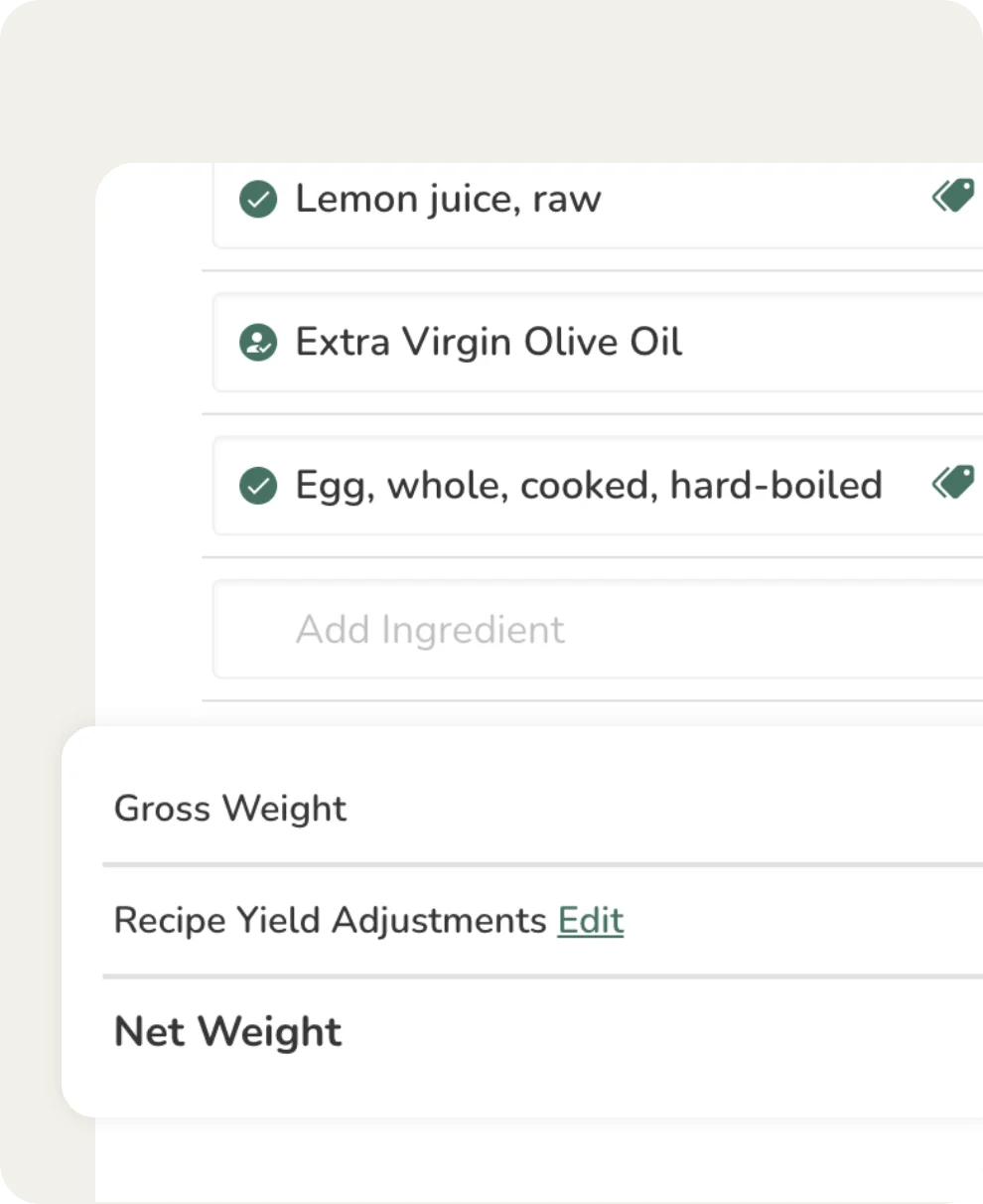

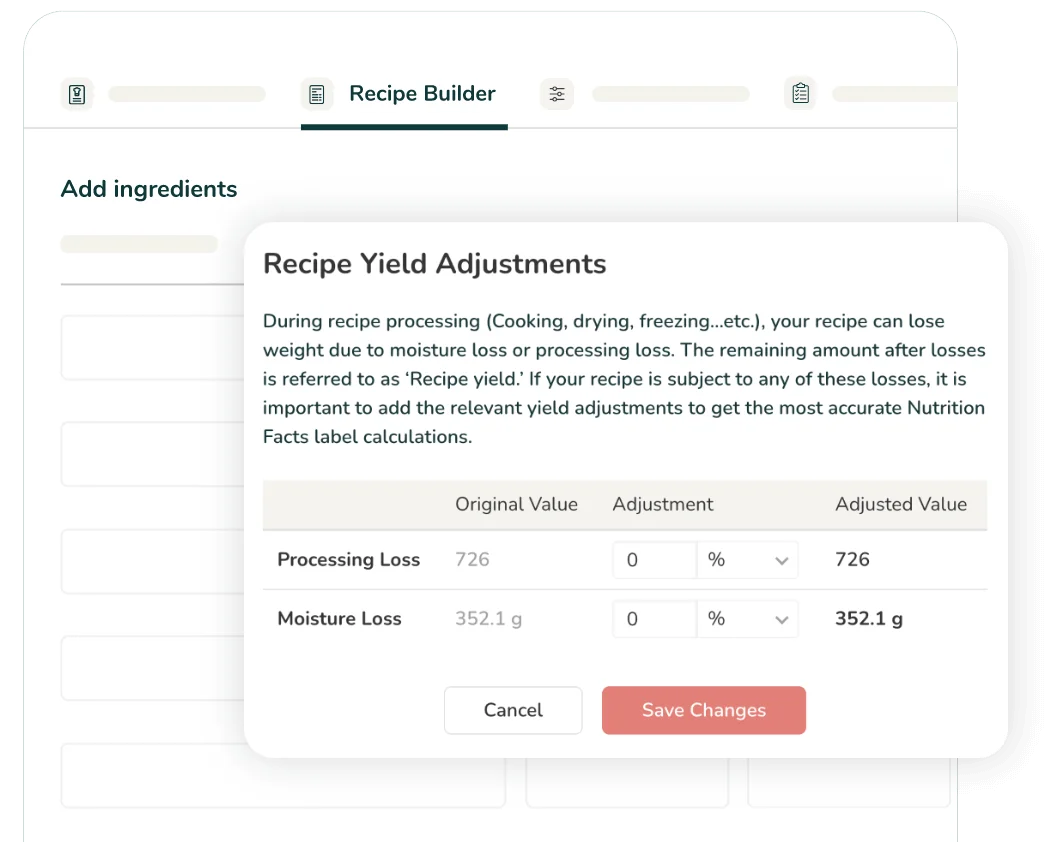

To change the yield of a recipe (i.e., scaling it up or down), you typically adjust the quantities of all your recipe ingredients proportionally based on your chosen conversion factor. When scaling ingredients for recipe production, it’s critical to also account for processing loss or moisture loss (common during cooking or drying).

Our recipe yield adjustment software simplifies this process, allowing you to adjust your processing and moisture loss, ensuring the final yield and serving size are accurate for all your recipes and food labels.

To find the conversion factor for scaling a recipe, you use the formula:

Desired Yield ÷ Original Yield = Conversion Factor

For example, if your original chocolate cake recipe makes 10 slices, but you need 30 slices, the conversion factor would be 30÷10=3. You would then just need to multiply all your recipe ingredients by 3.

However, for recipe yield adjustment (accounting for losses), the process is more complex. Our software allows you to input specific formulas for moisture loss or processing loss (e.g., as a percentage or fixed weight). Our tool then automatically calculates the necessary raw ingredient quantities to achieve your desired final yield after these losses. This allows you to create accurate recipes without the need for complex or time-consuming manual calculations.

To ensure accuracy in recipe yield adjustments, precise measurement procedures are essential. This includes:

- Pre-Process Measurement: Accurately weighing all your recipe ingredients before any cooking or processing begins.

- Post-Process Measurement: Weighing the final prepared product after cooking, drying, or cooling to determine the actual yield.

- Loss Calculation: Determining the difference between the initial total raw weight and the final cooked weight to calculate the exact moisture loss or processing loss. This loss can then be expressed as a percentage or a specific weight.

Our recipe yield adjustment software simplifies these procedures by providing a structured system to input pre- and post-process data, apply loss formulas, and automatically calculate and adjust all your recipes for compliance and quality control.

When doubling a recipe, while the general rule is to multiply all your recipe ingredients by two, you should also consider the following factors, especially for large batches that you need to produce in a certain timeframe:

- Cooking Time: Liquids might evaporate faster or slower, and dense items may take longer to cook through. You should provide yourself with slightly more cooking time rather than simply doubling the time, especially for poultry or meat products.

- Equipment Size: Ensure you have larger kitchen equipment that can handle the larger batch, as overfilling can affect cooking time or loss from ingredients spilling out.

- Seasoning: Spices and strong flavorings might not need to be exactly doubled; add gradually and taste as you go.

- Moisture Loss/Evaporation: Larger batches might require a larger surface area for cooking, and this could affect moisture loss. Our recipe yield adjustment software can help account for these nuances in a production setting.

- Mixing: For recipes that require combining different ingredients, like a cake or a salad, your equipment should be large enough to handle more ingredients for proper mixing.

These considerations help ensure the quality, consistency, and final yield of the doubled recipe remain as intended.